Control Unit

- Drive & Control System

- Control Unit

- FEATURE

- TDR-series, as an all-digital type lifting magnet controller developed by HANMI TECHWIN. CO. LTD., is a device which imposes 3 phase AC voltage by converting into DC voltage using a power driving component SCR(thyristor) and controlling the size of the output voltage and the output current.

It is essentially utilized in iron and steel manufacture related fields, iron and steel products of various industrial fields and logistics, transportation and cargo handling of material fields, and it is an essential system for automation and rationalization of industrial facilities.

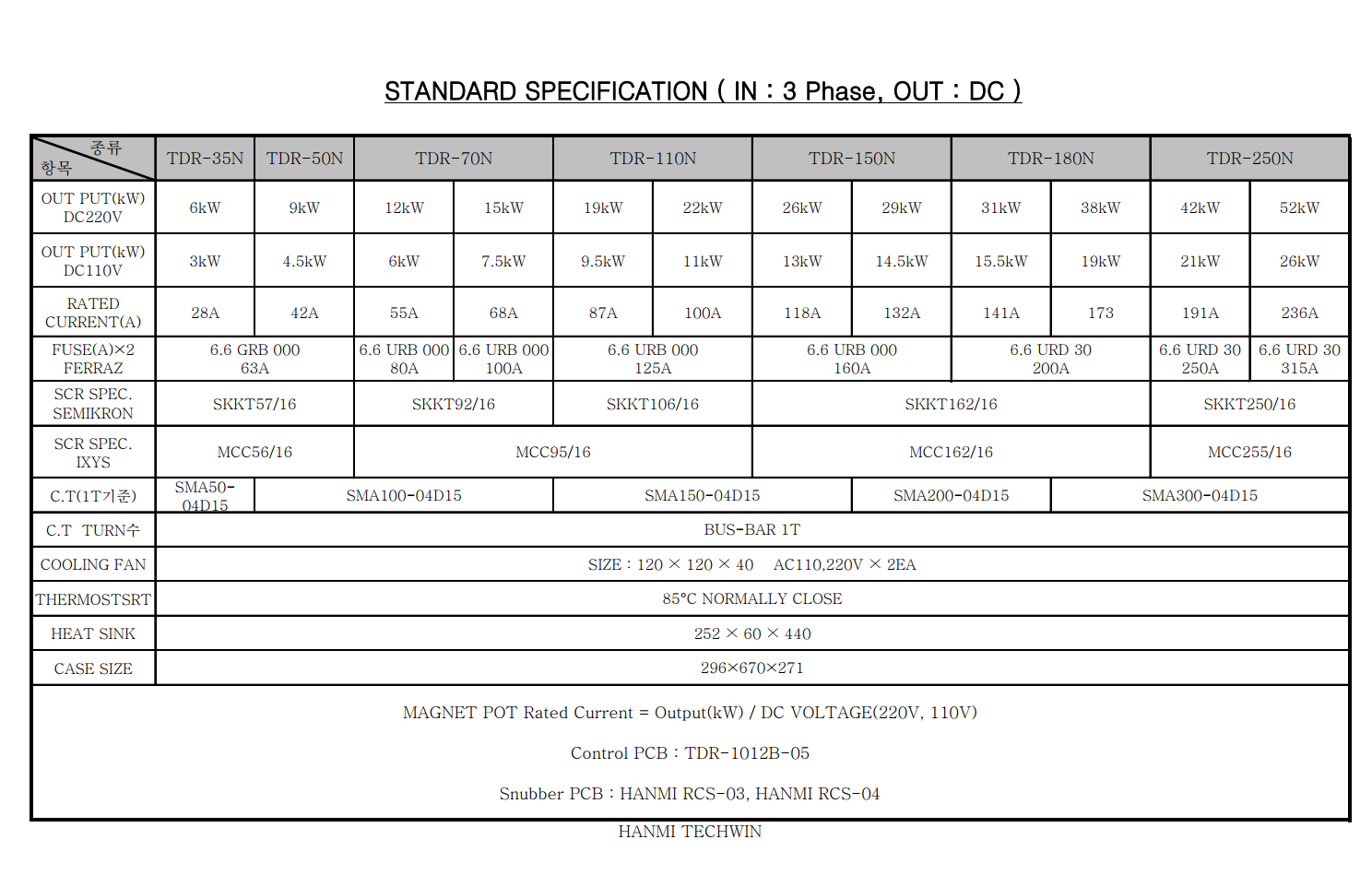

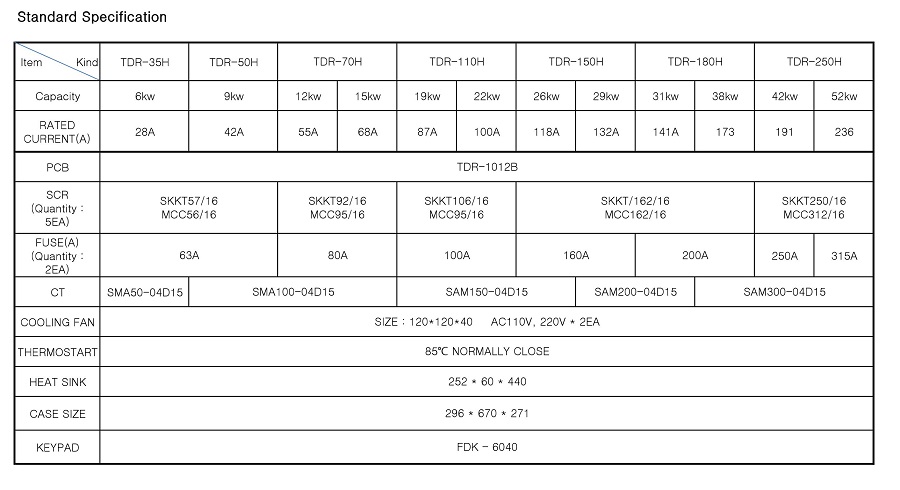

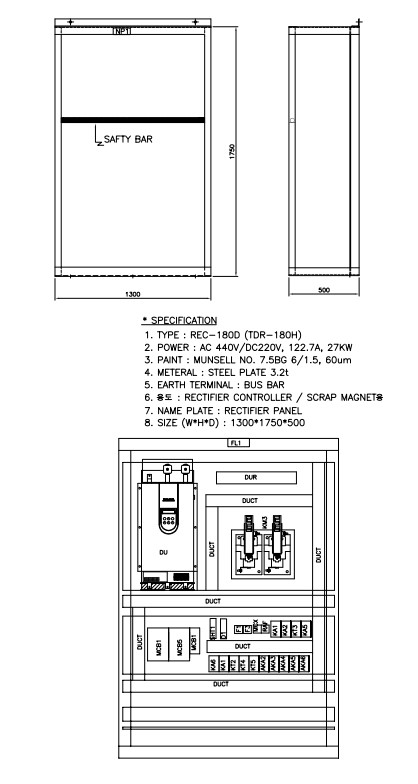

Standard Specifications

Option

* Parameter setting

1. Set according to magnet port type: * Magnet Select - permanent (electromagnet) or Electro

(electromagnet) selection

2. Rated Voltage (V): Magnet Pot (W) = Rated Current (A) * Rated Voltage (V)

3. * C / T Rating Setting: It is setting for C / T capacity which is received by PCB and set to C / T

installed in the stack.

4. Set the limit value of voltage and current

: Limit Current - Limit current above set value, set Rated Current * 1.5

: Limit Voltage - Limit voltage above set value. Set Rated Voltage * 1.5

5. Setting according to the operation input method: Control Input - Switch (stick input method), Analog,

Mixed (Potential input method)

※ When using Permanent (Electro Magnet), the notch level should be same when LIFT / DROP is operated.

Features

(1) Drop start operation by using 3 phase

(2) Positive / negative phase detection of input R, S, T: phase detection can be detected

(3) Resistant to abnormal signal by applying special filter to input power

(4) Accurate control by DC current detection: Current control possible

(5) RCB power supply free voltage (AC90 ~ 240 [V]): It can be used even if voltage drop and battery power is low

(6) Possible to use both electromagnet and electromagnet

(7) Prevent contact failure by removing PCB socket: It can be used in harsh environments such as temperature and dust