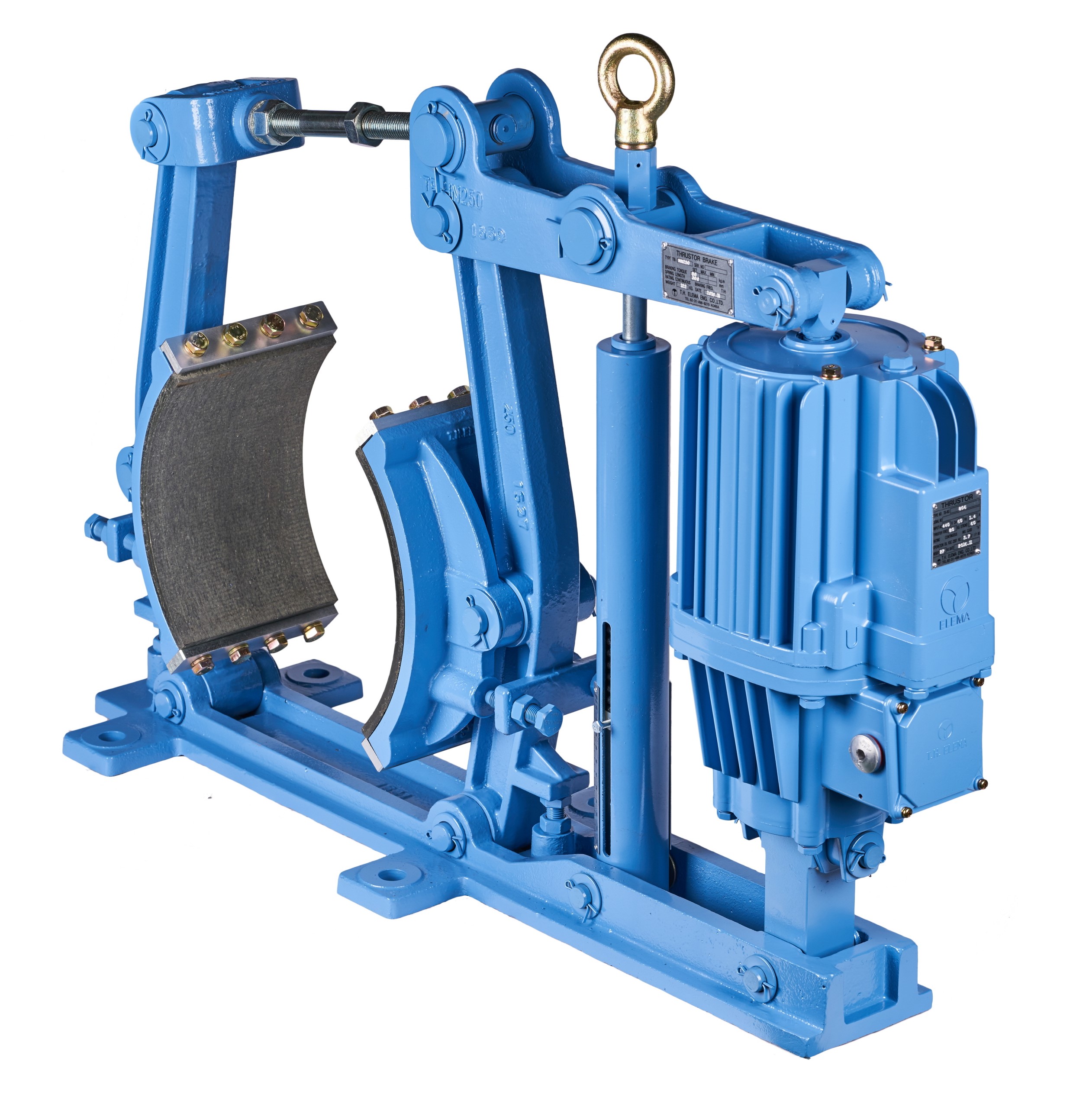

Oil Thrustor Drum Brake

- Brake

- Oil Thrustor Drum Brake

- Oil Thrustor Drum BrakeDrum One Post Thrustor Brake

- FEATURE

- This brake is mainly used for the travelling and traversing motion of a crane and also various kinds of

machinery equipment.

This is an oil type thrustor which covers perfectly the weak points of the two post type thrustor and other thrustors. Therefore, we developed the new type of one post type.

And also we have minimized the weight(54% lighter than two post type), precision and the effect of heat dissipation(more than three times cooler comparing with the two post type) because the body of the thrustor

is die casted with aluminium.

Brake Cover (HN180용)

Standard Specification & Dimension

Option Specification & Dimension

Special Type

Brake Cover

Brake Cover (HN355용)

Standard Specifications

* Enclosure Type : Dustproof, Waterproof (IP65)

* Installation Method : Horizontal base plate (±40°)

* Input : AC480 / 440 /380 / 220V, 3Φ, 50 / 60Hz

* Allowable Power Source Fluctuation

Voltage : -15 ~ +10%

Frequency : ±5%

* Max. Duty Frequency : 600 times / Hr

* Duty Cycle : 60%ED, Continuous

* Insulation Class : Class H

* Paint Color : Munsell No. 2.5PB 5/6

* Thrustor Oil : KSC 2301, OT4

| Global Maker | SHELL | CALTEX | NYNAS | SK |

| Product Name | SHELL DIALA S4 ZX-I |

GS TRANS 1 |

-Nytro Libra -Taurus |

SK

SUPER VOLT R |

Option

* Automatic Gap Adjuster

* Manual Releasing Device

* Brake Cover : For Outdoor Use Only

* Limit Switch

* When apply to Conveyor, continuous duty is possible more than 3 days (72 Hours),

and manufacture is possible separately by option.

Features

(1) Perfect Oil Leakage Prevention

The upper five stages and the lower two stages of seals are installed.

It is configured to enable sealing.

(2) High Effectiveness and Reliability

It can be used with confidence even in heavy duty conditions such as continuous operation or high frequency use.

(Number of movements: 600 times / hour)

Degree of protection : IP65

(3) Meet Various Installation Conditions

Existing thrustor was possible only in horizontal installation condition of Brake, but newly developed TB-HN Type Brake is

It is configured to enable sealing.

(2) High Effectiveness and Reliability

It can be used with confidence even in heavy duty conditions such as continuous operation or high frequency use.

(Number of movements: 600 times / hour)

Degree of protection : IP65

(3) Meet Various Installation Conditions

Existing thrustor was possible only in horizontal installation condition of Brake, but newly developed TB-HN Type Brake is

completely sealed structure even at ± 40 ℃. Normal operation is possible.

(4) Lightweight

The weight of this thrustor is around 54% lighter than the previous two post ones because the thrustor is made of

die-cast aluminium and the surface temperature stays below 60℃ even if it is used with high frequency operations,

since its thermal conductivity of cylinder is three times more than normal steel.

And also the brake frame is made with ductile, small and light structure.

(5) Structure

One post thrustor is composed of cylinder and motor, easy and simple for maintenance and easily removed from

each other by removing bolts only.

The T.B Box of the thrustor can easily be changed at one's disposal,

because the lower part of the thrustor is designed for easy assembly structure.

(6) Speed Adjusting Device (Open & Close)

The operation time of the thrustor can be adjusted up to 0.3sec ~ 6sec,

and used not only for hoisting motion (for quick braking) but also for travelling and traversing motion(for soft braking).

Longer than 6sec operation can be optionally available.

(7) No Oil Pollution

The thrustor has a long life, because the cause of pollution is eliminated by specialized coating on the inside of thrustor.

(8) No Greasing Necessary

It is not necessary to grease the frictional area of pin connection, because dry metal bushings are adapted thereto.